Shop Hull Size

Large or small, every Pro Boat radio control boat delivers phenomenal performance with head-snapping style. Pro Boat has compact RC boats ideal for fun runs in your backyard pool, as well as bigger, more powerful boats that are burning to go full-throttle across your local lake or pond. Pro Boat has you covered with the right RC boat for wherever the water is waiting!

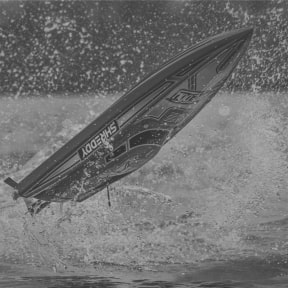

Shop Hull Type

The sculpted hulls of our radio control boats cut smoothly through the water to deliver the ultimate adrenalin rush. Hull types range from scale, to V-hulls, to catamarans, each having its own unique handling characteristics — just like their 1:1 counterparts. Find an RC boat with the perfect style and performance for you among the many choices at Pro Boat.

Pro boat Life

Pro Boat is more than a brand of radio control boats. It’s a community of boating enthusiasts like you who share a passion for the boating lifestyle. Smash that “Like” button, subscribe, and follow all of our social media channels to stay up-to-date on everything Pro Boat.